Sieved Lactose

MEGGLE has it.

Lactose for powder preparations.

Although tablets account for the majority of solid oral dosage forms, powder preparations, such as capsules and sachets, present viable options to the developer.

In early stages of formulation development and preparation of clinical trial material, capsules are the ideal choice. When the preservation and long term integrity of the gelatin capsule is needed, lactose is the RIGHT choice! Lactose has limited interaction with gelatin capsules and is the ideal capsule filler for formulators around the world. This clearly has not changed for Hydroxypropylmethylcellulose (HPMC) capsules, which have gained a lot of popularity.

Capsules are of special interest for early stage developments and clinical trials medication, where on a final formulation has not been decided yet.

Trend: Capsule and sachet formulation for children and elderly people.

When developing a powder preparation, processability of the final powder blend, as well as content uniformity and avoiding powder segregation is imperative to a successful development. This is critical for pediatric and geriatric medicines. These patient populations represent a need for enhanced delivery methods that circumvent impaired tablet-swallowing. Capsules and sachets are trending as more popular dosages and offer opportunities for gaining market share.

Key for content uniformity: Suitable particle size distribution as well as bulk density.

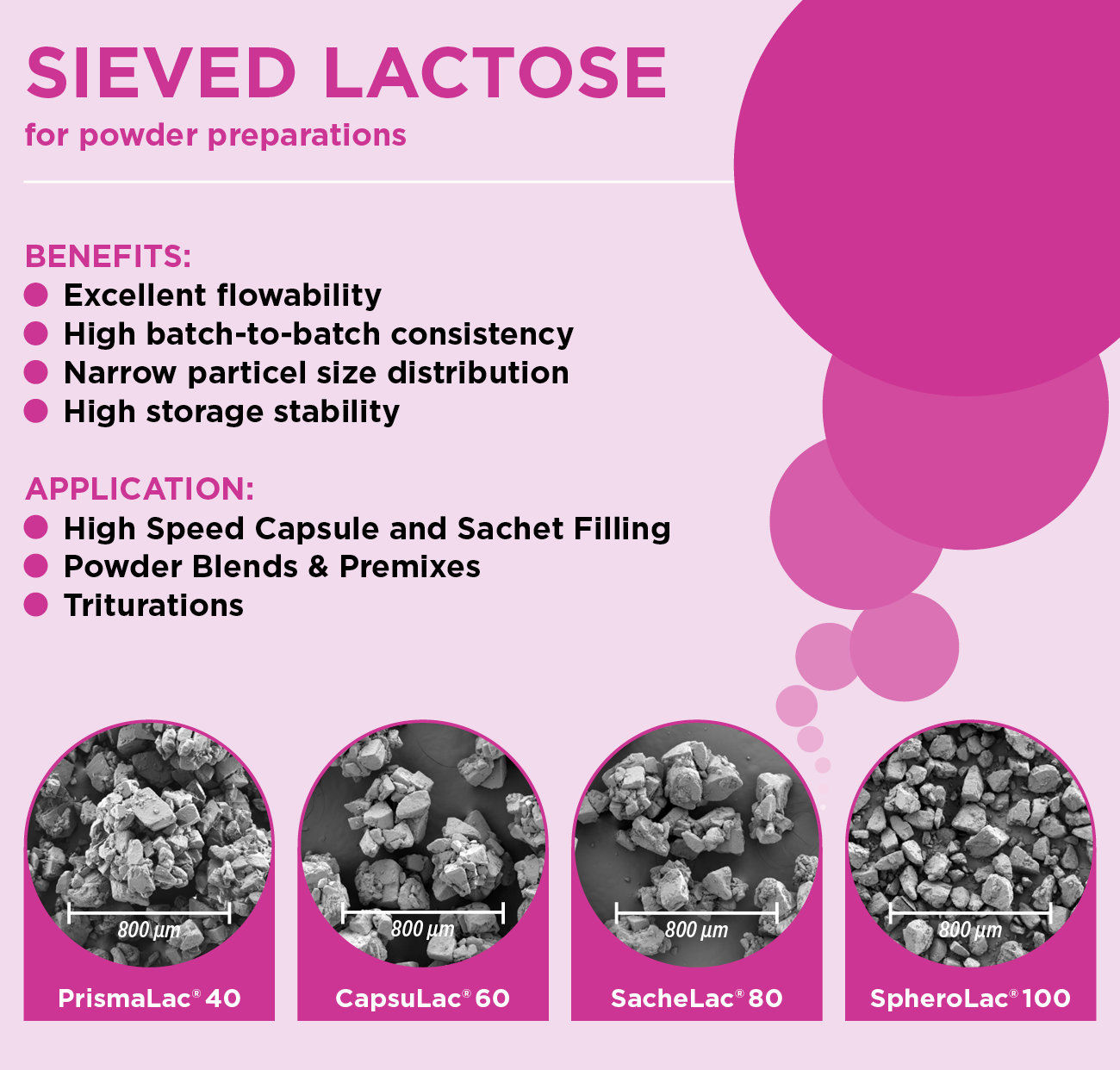

MEGGLE has decided to contribute to these needs in a meaningful way by providing a range of lactose grades which differ in particle size distribution as well as bulk density. Both parameters are essential to a successful formulation development. With the right excipient technology choice, content uniformity issues may be a minor obstacle – MEGGLE has it! In order to provide consistent functionality, MEGGLE has implemented a rigorous quality system, which exceeds current Good Manufacturing Practice (GMP).

MEGGLE´s expertise: Off the shelf products or tailor-made sieved lactose grades.

As MEGGLE aims to achieve ultimate customer satisfaction, it has partnered with leading capsule-filling-machine-manufactures in order to provide expertise from both ends; material and processing. By partnering with these companies, MEGGLE is also able to tweak and improve its products, which leads to improved off-the-shelf products but gives the customers also the option to choose a tailor-made grade for even better performance.

MEGGLE´s sieved lactose grades offer great features in high speed capsule filling.

Maximum comfort using MEGGLE lactose in high speed capsule filling is guaranteed. Custom, powder-engineered sieved Lactose grades allow for balancing important powder properties such as density, flow or cohesiveness. In an extensive case study (AAPS 2019) using a MG2 Planeta dosator capsule filling machine, material performance of a formulation comprising low dosage, ultrafine example API Vitamin B2 and coarse, lubricated lactose diluent SacheLac® 80 was investigated. Popular capsule sizes #1, #3, and #4 have been analyzed at 3 discrete filling speeds (15, 38, and 50k capsules/filling unit/h) at different time points according to content and weight uniformity and further performance-related parameters. All results indicated easy capsule filling at high efficiency and quality standards under given equipment design and compendial requirements.

MEGGLE lactose grades suitable for powder preparation e.g. high speed capsule and sachet filling are available under the trade names PrismaLac® 40, CapsuLac® 60, SacheLac® 80 and SpheroLac® 100.

Information / Sample request:

MEGGLE has it.

Lactose for powder preparations.

Although tablets account for the majority of solid oral dosage forms, powder preparations, such as capsules and sachets, present viable options to the developer.

In early stages of formulation development and preparation of clinical trial material, capsules are the ideal choice. When the preservation and long term integrity of the gelatin capsule is needed, lactose is the RIGHT choice! Lactose has limited interaction with gelatin capsules and is the ideal capsule filler for formulators around the world. This clearly has not changed for Hydroxypropylmethylcellulose (HPMC) capsules, which have gained a lot of popularity.

Capsules are of special interest for early stage developments and clinical trials medication, where on a final formulation has not been decided yet.

Trend: Capsule and sachet formulation for children and elderly people.

When developing a powder preparation, processability of the final powder blend, as well as content uniformity and avoiding powder segregation is imperative to a successful development. This is critical for pediatric and geriatric medicines. These patient populations represent a need for enhanced delivery methods that circumvent impaired tablet-swallowing. Capsules and sachets are trending as more popular dosages and offer opportunities for gaining market share.

Key for content uniformity: Suitable particle size distribution as well as bulk density.

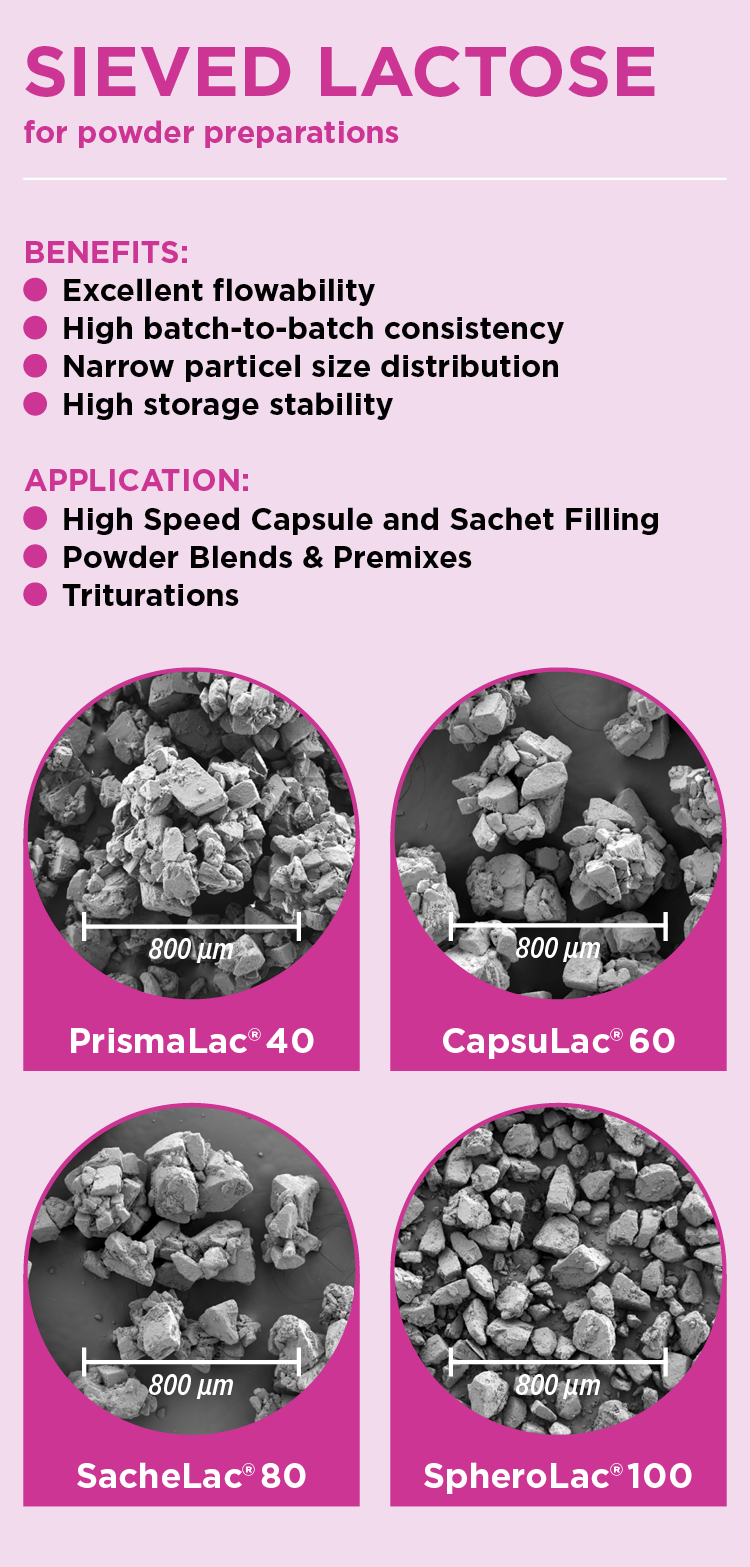

MEGGLE has decided to contribute to these needs in a meaningful way by providing a range of lactose grades which differ in particle size distribution as well as bulk density. Both parameters are essential to a successful formulation development. With the right excipient technology choice, content uniformity issues may be a minor obstacle – MEGGLE has it! In order to provide consistent functionality, MEGGLE has implemented a rigorous quality system, which exceeds current Good Manufacturing Practice (GMP).

MEGGLE´s expertise: Off the shelf products or tailor-made sieved lactose grades.

As MEGGLE aims to achieve ultimate customer satisfaction, it has partnered with leading capsule-filling-machine-manufactures in order to provide expertise from both ends; material and processing. By partnering with these companies, MEGGLE is also able to tweak and improve its products, which leads to improved off-the-shelf products but gives the customers also the option to choose a tailor-made grade for even better performance.

MEGGLE´s sieved lactose grades offer great features in high speed capsule filling.

Maximum comfort using MEGGLE lactose in high speed capsule filling is guaranteed. Custom, powder-engineered sieved Lactose grades allow for balancing important powder properties such as density, flow or cohesiveness. In an extensive case study (AAPS 2019) using a MG2 Planeta dosator capsule filling machine, material performance of a formulation comprising low dosage, ultrafine example API Vitamin B2 and coarse, lubricated lactose diluent SacheLac 80 was investigated. Popular capsule sizes #1, #3, and #4 have been analyzed at 3 discrete filling speeds (15, 38, and 50k capsules/filling unit/h) at different time points according to content and weight uniformity and further performance-related parameters. All results indicated easy capsule filling at high efficiency and quality standards under given equipment design and compendial requirements.

MEGGLE lactose grades suitable for powder preparation e.g. high speed capsule and sachet filling are available under the trade names PrismaLac® 40, CapsuLac® 60, SacheLac® 80 and SpheroLac® 100.